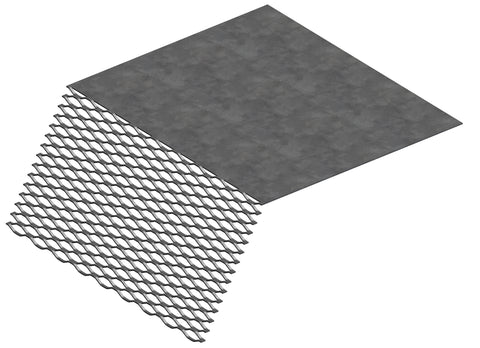

Expanded metal mesh products are produced from solid sheets of carbon steel, galvanized steel, or aluminium and other metals/alloys.

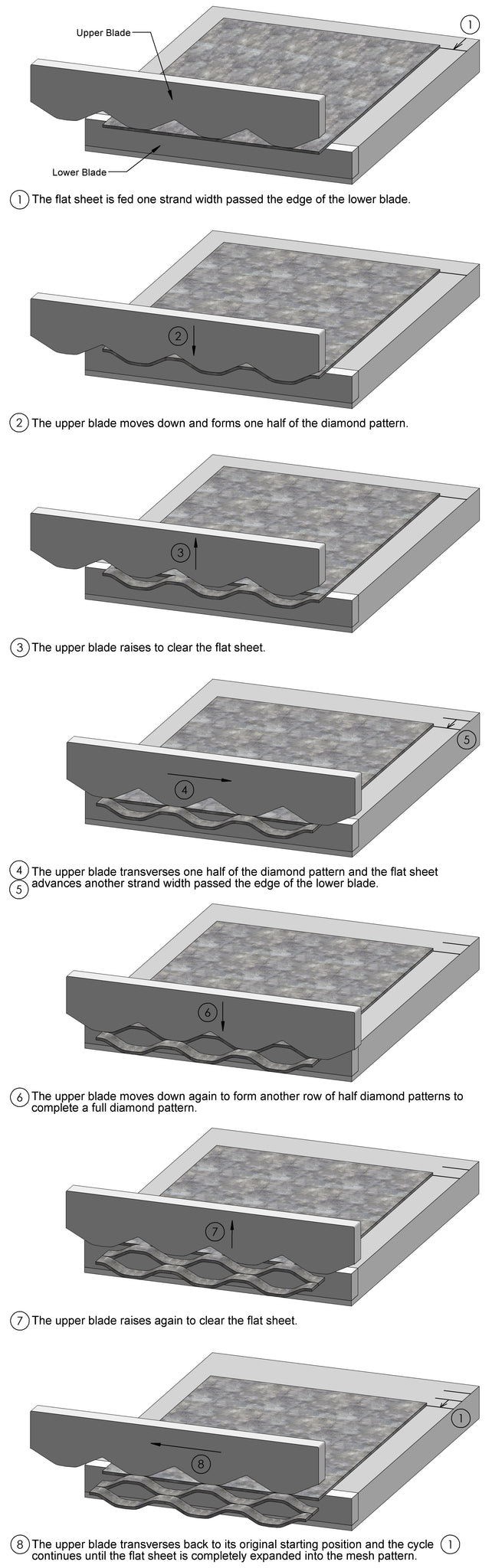

In the expanding process, the sheet is simultaneously slit and stretched, expanding the slits into diamond-shaped holes of uniform size, shape and regularity.

No metal is lost in the expanding process and the final product is stronger per kilogram and lighter per metre than the original sheet. The newly formed strands and knuckles of the diamond-shaped trusses are at an angle to the original plane of the sheet, adding strength and rigidity.

Because it is made from a solid sheet of metal, expanded mesh can never unravel. The metal strands which form the open diamonds of the new sheet permit light, heat, air, liquid, and sound to pass through, yet produce a virtually impenetrable barrier to larger solid objects. Even if the finished sheet is cut at one or more points, the remaining strand intersections continue to hold the sheet together.

While the diamond design may vary, this illustration shows how a solid flat sheet of material becomes expanded metal without any material waste. The result of this expanding operation is a product that is lighter per metre and stronger per kilogram than the original flat sheet from which it came.