Question: How strong is Expanded metal?

Answer: Expanded metal uses sheet metal as it's starting point of manufacture, therefore the Expanded metal exhibits the same strength characteristics as the sheet metal in it's finished manufactured from. It is not joined or welded, which results in a homogeneous product. Similarly, Expanded metal manufactured from alternative materials such as Aluminium, Copper, Brass, etc, will exhibit the same material strength properties as the original raw sheet used to manufacture the Expanded metal.

Question: Can Expanded metal be painted or coated?

Answer: Yes, like any manufactured item, surface coatings can be applied dependent on the base material. For example, Aluminium Expanded metal could be anodised, and most metals can be painted or powder coated quite successfully. Hot dip galvanising can also be applied to raw mild steel, however a minimum of 2mm raw material is recommended to avoid too much deformation from the hot baths and processes. Note, like any surface coating on flat material, the finish and durability is only as good as the preparation of the base surface. Often blasting and/or priming will be required.

Question: Can Expanded metal be folded?

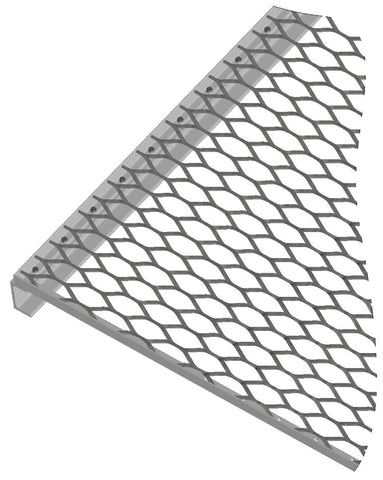

Answer: Yes, Similar to any sheet metal material, Expanded metal can be folded, rolled or formed into many shapes. Please note that there may be some limitations in the minimum radii used, or the degree of fold (angle). Differences may also be seen between different mesh profiles and materials/thicknesses used to manufacture the mesh.

Question: How do I attach expanded metal to surrounding structures?

Answer: There are many methods available for fastening and anchoring mesh. The mesh itself can be welded, riveted or screwed/bolted to mating structures. The mesh can alternatively be mounted into a panel frame that can then be attached to the surrounding structure. Often this is a preferred method so that easy surface coating and handling can be performed, as well as final bolting/mounting in place.

Question: What tolerances can you manufacture Expanded metal to?

Answer: Expanded metal can vary quite easily during the manufacturing process. However, Trussforte have a very dedicated team that ensure all mesh manufactured is within our specifications that can be found on our Manufacturing Tolerance page. In addition, we have an established set of mesh set up parameters that ensure there is limited variation between similar mesh made from different batches.

Question: What materials are suitable for use in manufacturing Expanded metal?

Answer: Expanded metal can be manufactured from a variety of different materials. Common materials used are Carbon steel (ie plain mild steel) or Aluminium (normally Grade 5005). Other materials such as Galvabond (metallic coated Carbon steel), Brass and Copper are also materials that we have successfully manufactured Expanded Metal from. Other materials may also be used, and we would be more than happy to discuss and trial alternative materials that you are considering for your project.

Question: What is the correct diamond orientation for a sheet of Expanded metal?

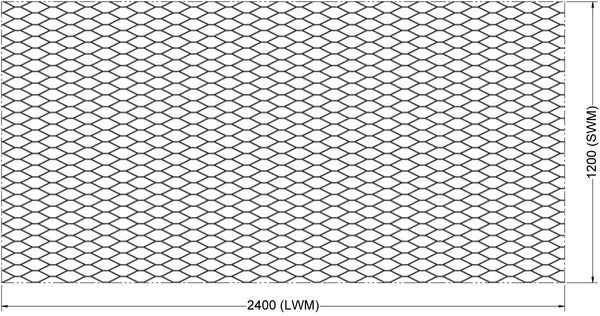

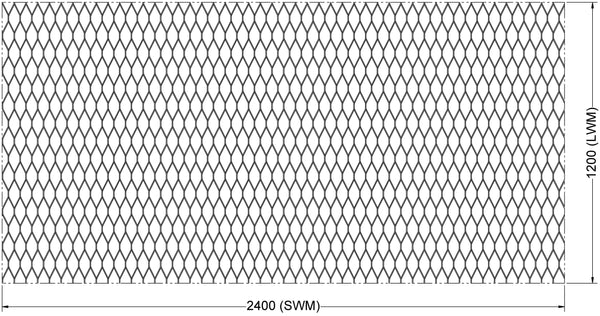

Answer: The orientation (direction) of the diamonds is described on our Understanding Mesh/Terminology page. Normally the Short Way Measurement (SWM) is the expanded direction of the sheet, with the Long Way Measurement (LWM) being the non expanded direction. The LWM is the raw material sheet size that is fed through our machinery that remains the same size (pre and post expansion size is the same). This is usually a function of raw material sheet size availability as well as machine/blade capacity. The conventional mesh sheet size designation that we use is stating the SWM first x the LWM.

Eg. D1620 1200 x 2400 would be Profile D mesh with a SWM of 1200mm x a LWM of 2400.

Eg. D1620 2400 x 1200 would be Profile D mesh with a SWM of 2400mm x a LWM of 1200.

Question: What does free air space refer to?

Answer: Free air space is the percentage of the viewable expanded sheet area that is space, as opposed to metal material. Please refer to the Understanding Mesh/Terminology page for a further explanation and schematic diagram.

Sometimes aesthetics are very importance, so elaborate fixing methods may be required to ensure that there is a pleasing appearance of the mesh and/or the surrounding building. Other times it may not be so importance, but there may be a requirement for easy removal for cleaning or access purposes.

For this reason we cannot advise that any one method is better than another. Below are some drawings of alternative ideas that may assist you with your design and fixing details.

For Gridmesh® mounted in a frame

For Gridmesh® directly fixed to support structure

For Gridmesh® fixed with a clamp plate/flat example 1 , and Gridmesh® fixed with a clamp plate/flat example 2

There are many methods for fixing Gridmesh® (as well as other mesh panels) to the surrounding platforms of structures and/or walkways. There is no one best method for this due to many variables that may be considered by Architects and Engineers.